Better EV battery packaging design should take into account multiple factors such as battery shape, weight, flammability, life cycle, cost and external environmental impact, and be able to meet various safety standards and regulations.

We have complete customized packaging solutions to help you improve transportation safety, logistics efficiency and environmental issues, and improve overall supply chain efficiency.

Make Safe, compliant and efficient

packaging and transportation for batteries

TECPACK-Perfect Supplier of

Power battery packaging and transportation solutions

It is complicated to pack and deliver vehicle batteries as they are highly regulated items. While there is a wealth of information on shipping requirements, how to design automotive battery packaging is still a grey area. Don’t be shocked if it takes a few attempts to get your design certified, it can be a long and frustrating process. Trial and error isn’t the easiest approach, but working with the right packaging solutions provider can ease that burden.

We have extensive experience in the design, packaging, and transportation of EV batteries. If you would like to learn more about how we can help you solve your lithium-ion battery packaging issues, please feel free to contact us!

Why TECPACK

To do Power battery packaging and transportation

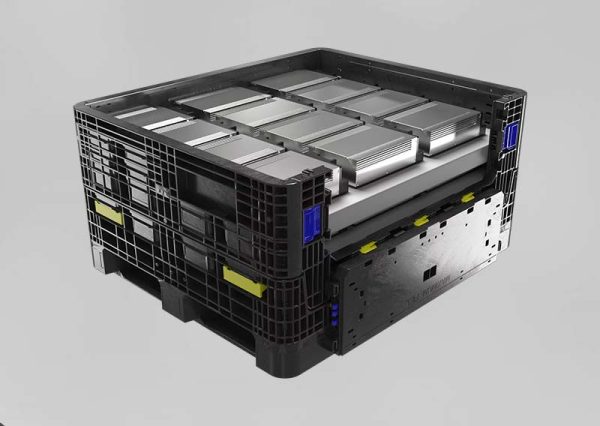

EV Battery Packaging and Shipping Solution for VOLVO

Taking the commission from Volvo, we help them design dangerous goods packaging - electric vehicle battery packaging.

TECPACK provides power battery packaging and transportation solutions for CATL

As a giant company that has ranked first in the world in power battery usage for four consecutive years as of 2020, it is obvious that they have high standards for power battery packaging.