For batteries with different appearances, materials and weight, there may be the following Difficulty points on their packaging:

1. Different shapes batteries require different packaging designs, which may increase production costs and complexity.

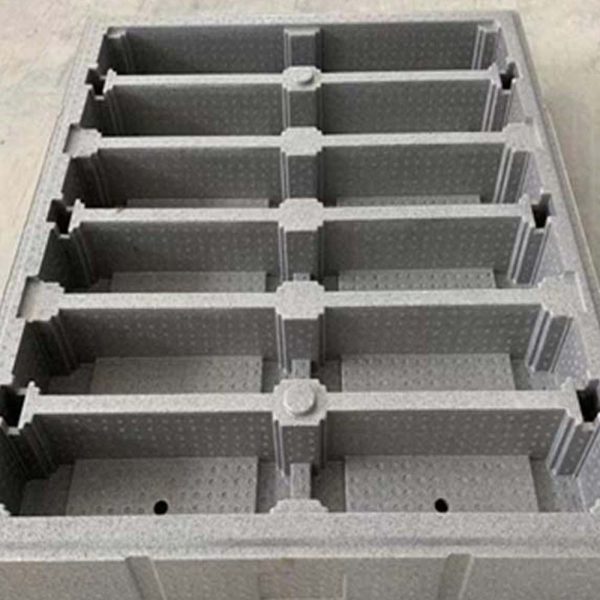

2. Different shapes batteries require different protection measures during transportation and storage, which may increase logistics costs and complexity. For example, cylindrical batteries may require special packaging designs to protect their surfaces from damage, while also considering how to avoid rolling and bumping of the batteries during transport and storage. Square or rectangular batteries may require special support structures to prevent the batteries from shifting and being damaged during transportation and storage.

3. Battery packaging needs to meet various safety standards and regulations, which may increase the cost and complexity of packaging design and testing.

4. Due to the weight and flammability of batteries, their packaging requires special handling and marking, which may increase logistics and storage restrictions and costs. For example, all lithium-ion batteries must be transported in a manner that prevents: short circuits, movement within the outer packaging, and accidental activation of the device.